Comprehensive Analysis of Die-Casting Process: Principle, Types, Applications, and Advantages and Disadvantages Comparison

Die casting is a precision casting method that uses high pressure to force molten metal into a metal mold with a complex shape. The following is a detailed introduction to the die-casting process:

Principle of Die-Casting Process

Liquid or semi-liquid metal is filled into the cavity of a mold (pressure mold) at high speed and high pressure, and then formed and solidified under pressure to obtain a casting.

Types of Die-Casting Process

Hot chamber die casting: The injection part is installed on the crucible and immersed in the liquid metal in the insulated melting crucible. It is suitable for low-melting-point metals such as zinc, tin, and lead alloys. It has the advantages of fast cycle speed, easy automation, and convenient metal melting. However, it cannot be used for high-melting-point metals and aluminum, and it is difficult to use for large castings.

Cold chamber die casting: The metal needs to be melted in an independent crucible first, and then a certain amount of molten metal is transferred to an unheated injection chamber or injection nozzle and injected into the mold through hydraulic or mechanical pressure. It is used for aluminum, magnesium, copper, and zinc alloys with a high aluminum content. The disadvantage is a long cycle time. Cold chamber die-casting machines are also divided into vertical (usually small machines) and horizontal (with various models).

Die-Casting Process

Mold preparation: Spray lubricant into the mold cavity to control the mold temperature and assist in the demolding of the casting.

Filling: Close the mold and inject the molten metal into the mold with a high pressure of 10 - 175 megapascals to quickly fill the mold. Even thin-walled parts can avoid surface discontinuities, but it may cause air entrapment.

Injection: After the molten metal fills the mold, the pressure is maintained until the casting solidifies.

Shakeout: Separate the residues, such as the sprue, runner, gate, and flash. This can be done by trimming the mold extrusion, sawing, grinding, etc. The excess sprue can be melted and reused.

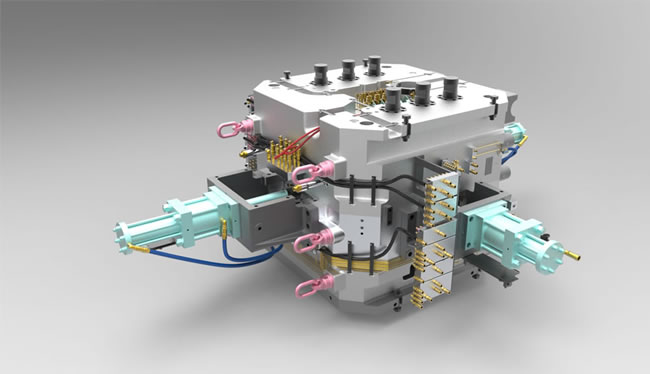

Die-Casting Mold

It consists of a cover part and a movable part, and the joint is the parting line. In hot chamber die casting, the cover part has a sprue, and in cold chamber die casting, it has an injection port. The movable part includes push rods and runners. In addition, there are components such as core slides in the mold. The core is used to create holes or openings in the casting to add details. There are three types: fixed, movable, and loose. The slide can create undercut surfaces.

Die-Casting Materials

Commonly used die-casting materials include aluminum alloys, magnesium alloys, brass, bronze, etc. Different materials have different requirements for the minimum cross-sectional area and minimum draft angle, and the thickest section should generally be less than 13 millimeters.

Advantages and Disadvantages of Die-Casting Process

Advantages: High production efficiency and simple process; high tolerance grade and good surface roughness of die-cast parts; high mechanical strength, which can eliminate a large number of machining processes and equipment and save raw materials.

Disadvantages: High process cost, related to mold creation and tooling; The mold is produced with molten steel, which limits the ability to conduct experiments and make prototypes. It is not suitable for single parts, prototypes, or small-batch production.

Application Fields

The die-casting process is widely used in fields such as automotive engineering (e.g., engine cylinder heads, transmission cases, brakes), aerospace, electronics, home appliances, medical devices (e.g., surgical instruments, artificial joints), and transportation facilities (e.g., railway facilities, power facilities).