Sheet Metal Fabrication: The Magical Transformation of Metal Sheets

In the vast system of modern manufacturing, sheet metal fabrication is like a low - key but highly skilled artist, silently shaping the prototypes of various metal products. From the casings of electronic products we use daily, to the body parts of cars, and then to the cabinets of industrial equipment, the presence of sheet metal fabrication can be found everywhere. It endows metal sheets with new forms and values, enabling seemingly ordinary metal materials to become practical objects that meet various needs after a series of elaborate processes.

Definition and Scope of Sheet Metal Fabrication

Sheet metal fabrication is a comprehensive cold - working process for metal sheets (usually less than 6mm thick). The term "cold - working" means that the entire processing process is basically carried out at room temperature, avoiding changes in metal properties caused by high temperatures. It encompasses a wide variety of operations, including shearing, punching/cutting/combining, bending, welding, riveting, splicing, and forming. It is worth noting that a significant feature of sheet metal parts during processing is that the thickness of the same part remains basically the same. This characteristic not only determines the uniqueness of sheet metal fabrication but also poses high requirements for processing accuracy and process control.

In daily life, sheet metal parts are ubiquitous. The chimney at home is made by shearing, bending, and welding metal sheets, achieving smooth smoke exhaust. The sturdy casing of the street distribution box is crafted through sheet metal fabrication, providing reliable protection for internal electrical components. The car's shell is a masterpiece of sheet metal fabrication. The complex curved surface shapes and high - precision splicing not only ensure the vehicle's aesthetics but also relate to driving safety. Behind these seemingly ordinary items lies the wisdom and craftsmanship of sheet metal fabrication.

Key Equipment for Sheet Metal Fabrication

Shearing Machine: As the basic equipment for sheet metal processing, the shearing machine is responsible for cutting metal sheets into the Preset size. It uses the relative movement of the upper and lower blades to apply shear force to the sheet, achieving straight - line cutting. Common shearing machines come in two types: mechanical transmission and hydraulic transmission. The mechanical shearing machine has a simple structure and low cost, making it suitable for cutting ordinary sheets in small - scale sheet metal processing plants. The hydraulic shearing machine, on the other hand, has the advantages of large shear force, high precision, and stable operation. It is more suitable for processing thicker sheets or scenarios with strict requirements for cutting precision. For example, in the production of large - scale electrical equipment casings, the hydraulic shearing machine can ensure that the dimensional error of sheet cutting is extremely small, laying a good foundation for subsequent processing.

CNC Punch Press: The CNC punch press is an efficient and precise stamping equipment. Through a pre - written CNC program, it can control the punch to quickly and accurately perform operations such as punching, blanking, and forming on the sheet. Compared with traditional punch presses, the CNC punch press has a high degree of automation, can process holes and contours of complex shapes, and has high processing precision, effectively reducing errors caused by manual operation. In the production of electronic equipment components, it is often necessary to punch a large number of tiny and precise holes in thin sheets. The CNC punch press can efficiently and stably complete the task with its advantages, greatly improving production efficiency and product quality.

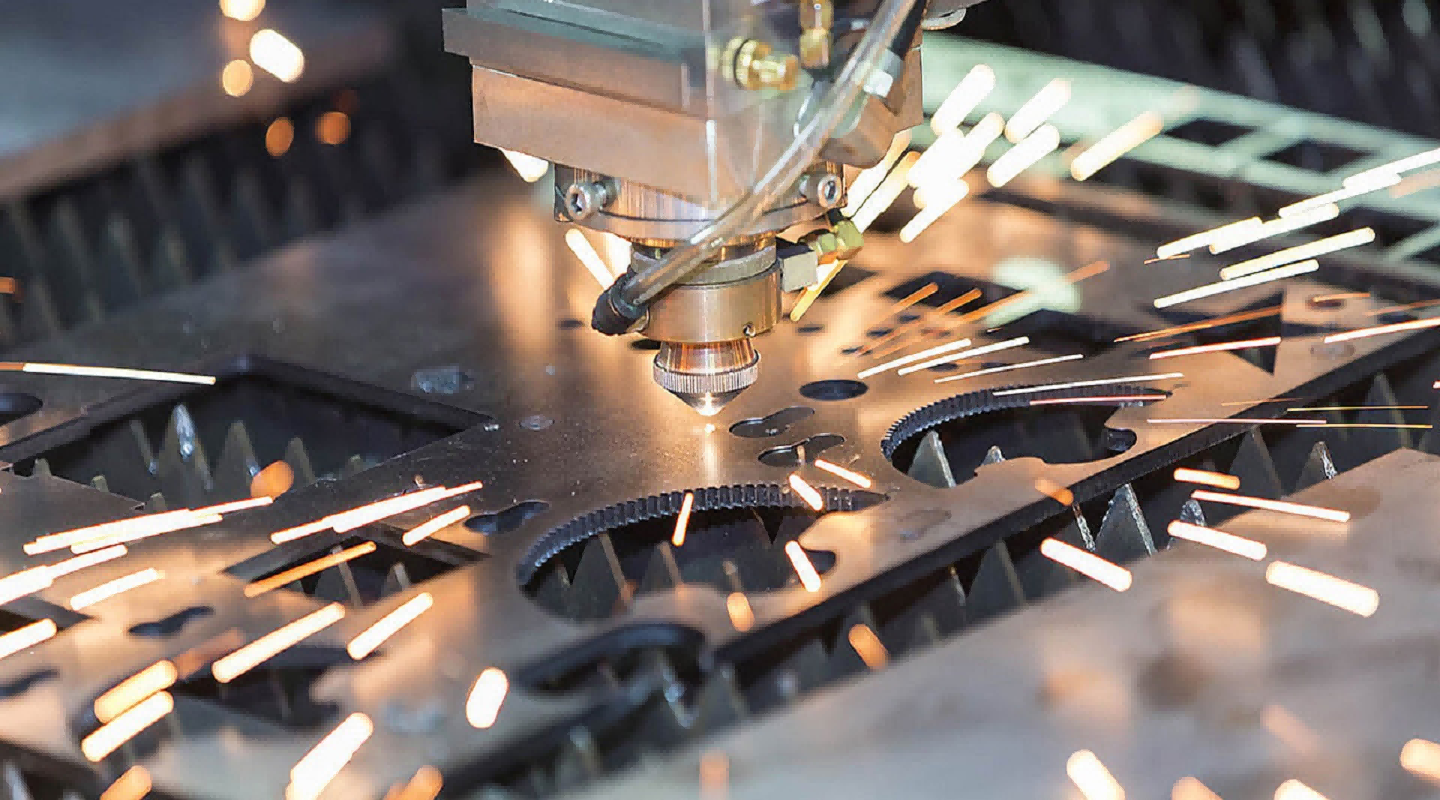

Laser Cutting Machine: The application of laser cutting technology in the field of sheet metal processing is becoming increasingly widespread, and the laser cutting machine has become an indispensable equipment. It uses a high - energy - density laser beam to irradiate the metal sheet, causing the sheet to melt or vaporize instantly, thereby achieving cutting. Laser cutting has many significant advantages, such as extremely high cutting precision, up to ±0.1mm or even higher, which can meet the requirements for processing fine parts; the cutting surface is smooth with almost no burrs, reducing subsequent grinding processes; it has strong adaptability to materials and can cut various metal materials, including difficult - to - process materials such as stainless steel and aluminum alloy; and it can cut workpieces of complex shapes, whether it is special - shaped patterns or delicate hollow designs. In the sheet metal processing of high - end electronic product casings and aerospace components with extremely high requirements for precision and complex shapes, the laser cutting machine plays a key role.

Bending Machine: The bending machine is used to bend metal sheets at a Specified angle and shape. It is an important equipment for shaping the three - dimensional shape of sheet metal parts. It mainly consists of a machine body, a workbench, a slider, a mold, and other parts. During operation, the sheet is placed on the workbench, and the slider drives the upper mold to move downward, cooperating with the lower mold to apply pressure to the sheet, causing it to undergo plastic deformation and form the required bending angle. The precision and stability of the bending machine directly affect the bending quality. Advanced CNC bending machines can precisely control the bending angle, stroke, and speed, ensuring the consistency of bending dimensions for products in the same batch. In the field of architectural decoration, when making aluminum alloy door and window frames, the bending machine can precisely bend aluminum profiles to create beautiful and sturdy door and window frames.

Main Processes of Sheet Metal Fabrication

Workpiece Blanking: After receiving the drawing, it is necessary to select the appropriate blanking method according to the developed drawing and production batch. Common methods include laser cutting, CNC punch press processing, shearing machine cutting, and die stamping. CNC punch press processing is fast and suitable for blanking workpieces with regular shapes and simple hole patterns in batch production. However, for the processing of special - shaped workpieces and irregular holes, there may be relatively large burrs on the edges, which require subsequent deburring treatment, and it has a certain impact on the workpiece accuracy. Laser cutting has no tool restrictions and can process workpieces of various complex shapes, with a flat and smooth cross - section. However, for small workpieces, the processing time is relatively long. The shearing machine is mainly used to cut sheets into rectangular blanks. It is simple to operate, has low cost, and is suitable for basic blanking with low requirements for shape. Die stamping has advantages in mass - producing workpieces of specific shapes, with high production efficiency and low cost. However, the die manufacturing cycle is long, the cost is high, and the flexibility is poor. After blanking, the edges, burrs, and joint parts of the workpiece need to be trimmed. For the tool joint, a flat file can be used for careful trimming; for parts with large burrs, a grinding machine can be used; for small inner - hole joints, a corresponding small file can be used to ensure the beautiful appearance of the workpiece and provide a guarantee for the precise positioning of subsequent bending and other processes.

Subsequent Processing Procedures:

Bending: Bending is a key process for giving the sheet metal part a three - dimensional shape. First, it is necessary to accurately select the bending tool and die groove according to the drawing dimensions and material thickness to avoid deformation caused by the collision between the product and the tool. The selection of the upper die needs to comprehensively consider the product shape and size, and the same product may use multiple types of upper dies; the lower die is determined according to the sheet thickness. Determining the bending sequence is also very important. Generally, the principle of "inside first, outside later; small first, large later; special first, ordinary later" is followed. For workpieces that need to be pressed to a dead edge, they are usually bent to 30° - 40° first, and then pressed to a dead edge with a leveling die to ensure the bending effect and dimensional accuracy.

Press Riveting: Press riveting is often used to fix parts such as nuts and studs on sheet metal parts. During operation, it is necessary to select the appropriate mold according to the stud height and accurately adjust the pressure of the press to ensure that the stud is flush with the workpiece surface. If the press - riveting force is improper, it may cause the stud to be not firmly pressed or protrude from the workpiece surface, resulting in workpiece scrap. In the production of the sheet metal casing of electronic products, press - riveted nuts are used to install internal circuit boards and other components, and their firmness directly affects the overall performance and stability of the product.

Welding: Welding is an important means of connecting multiple sheet metal parts to form a complete product. Common welding methods in sheet metal processing include argon arc welding, spot welding, carbon dioxide shielded welding, and manual arc welding. Spot welding is suitable for thin - sheet connection. During operation, the welding position of the workpiece needs to be considered first. In mass production, a positioning fixture can be made to ensure the accurate spot - welding position. To ensure firm welding, convex points can be made on the welding part of the workpiece to make the workpiece contact evenly before energized welding, and at the same time, determine the welding position. In addition, parameters such as pre - pressing time, holding time, maintaining time, and resting time need to be accurately adjusted to ensure spot - welding quality. After spot welding, there may be welding scars on the workpiece surface, which need to be ground with a flat grinder. Argon arc welding is suitable for the connection of larger workpieces or edge treatment, which can make the workpiece surface flat and smooth. However, the heat generated during the welding process is likely to cause workpiece deformation, and the workpiece needs to be trimmed with a grinder and a flat grinder after welding. In the manufacture of automobile bodies, a large number of sheet metal parts are connected into a whole by welding, and the welding quality is directly related to the strength and safety of the vehicle body.

Surface Treatment: After processes such as bending and press riveting, the workpiece needs to be surface - treated to improve its corrosion resistance, aesthetics, and other properties. The surface treatment methods for different sheets vary. Generally, cold - rolled sheets are electroplated after processing. After electroplating, they are usually not sprayed but subjected to phosphating treatment and then sprayed. Electroplated sheets need to be surface - cleaned and degreased first and then sprayed. Stainless steel sheets (such as mirror - finished sheets, matte - finished sheets, and brushed sheets) can be brushed before bending. If spraying is required, they need to be roughened first to enhance the coating adhesion. Aluminum sheets are generally anodized. The corresponding anodizing base color is selected according to the spraying color, and the commonly used ones are black and natural anodizing. If spraying is required, chromate anodizing treatment is also needed. Surface pre - treatment can effectively clean the workpiece surface, significantly improve the coating adhesion, and double the corrosion resistance of the coating. The cleaning process usually involves hanging the workpiece on the assembly line, passing it through the cleaning solution (such as alloy degreasing powder), clean water, and the spraying area in turn, and finally entering the drying area. After cleaning, the workpiece is removed from the assembly line.

Assembly and Packaging: The workpiece after surface treatment enters the assembly process. Before assembly, the protective stickers used during spraying need to be removed, and it is necessary to check whether there is paint or powder in the internal threaded holes of the parts. Gloves need to be worn during operation to prevent dust on the hands from contaminating the workpiece, and some workpieces also need to be blown clean with an air gun. After assembly, it enters the packaging stage to protect the workpiece. Workpieces with special packaging are put into special packaging bags; those without special packaging are wrapped with packaging materials such as bubble wrap. For large - batch production, special packaging materials such as cartons, bubble bags, rubber pads, pallets, or wooden boxes can be customized. The packaged workpiece is put into the carton, and the corresponding finished - product or semi - finished - product label is pasted on the carton for easy identification and management.

Advantages and Application Fields of Sheet Metal Fabrication

Advantages:

High Processing Precision: With the help of advanced CNC equipment and precision molds, sheet metal fabrication can achieve high - precision processing, and the dimensional tolerance can be controlled within a very small range, meeting the requirements of industries with strict precision requirements for parts, such as aerospace and electronics.

High Production Efficiency: The application of automated equipment such as CNC punch presses and laser cutting machines has greatly increased the speed of sheet metal processing. Especially in batch production, it can quickly complete the processing of a large number of workpieces, reducing production costs.

High Material Utilization Rate: Through reasonable nesting and optimized processing technology, sheet metal processing can minimize material waste, improve material utilization, and reduce the enterprise's raw material costs.

Product Diversity: Sheet metal fabrication can perform a variety of processing operations on metal sheets, enabling the manufacture of products with complex shapes and diversification, meeting the personalized needs of different industries and customers.

Application Fields:

Electronics Industry: In electronic products such as mobile phones, tablets, and computer hosts, sheet metal fabrication is used to manufacture casings, heat sinks, shielding covers, and other components. These sheet metal parts not only provide physical protection for internal electronic components but also play roles in heat dissipation and electromagnetic shielding, ensuring the stable operation and performance of electronic products.

Automobile Industry: Many parts of the automobile body, such as doors, engine hoods, and trunk lids, are composed of sheet metal parts. Sheet metal fabrication plays a crucial role in automobile manufacturing, and its processing quality directly affects the appearance, safety, and overall performance of the automobile. At the same time, some decorative parts and brackets in the automobile interior are also made by sheet metal fabrication.

Communication Industry: The cabinets and antenna covers of communication base stations mostly use sheet metal structures. The sheet metal cabinet has good protection performance and can effectively protect internal communication equipment from the external environment. The antenna cover needs to have specific electromagnetic properties and mechanical strength, and sheet metal fabrication can meet these requirements, ensuring the stable transmission of communication signals.

Architectural Decoration Industry: In the field of architectural decoration, sheet metal fabrication is used to make various metal decorative lines, shaped plates, ventilation ducts, etc. For example, the metal decorative shapes in hotel lobbies, the aluminum alloy door and window frames of office buildings, and the ventilation system ducts inside buildings all demonstrate the application of sheet metal fabrication in architectural decoration, which is both beautiful and practical.

Medical Equipment Industry: Medical equipment has extremely high requirements for the precision, reliability, and hygiene of components. The medical equipment casings, brackets, trays, and other parts made by sheet metal fabrication can meet these strict requirements, providing guarantee for the normal operation and safe use of medical equipment. For example, the casings of medical imaging equipment and the support structures of operating tables all rely on sheet metal fabrication.

Cutting - Edge Development and Challenges of Sheet Metal Fabrication

(1) Intelligent and Automated Upgrades

With the advancement of Industry 4.0 and intelligent manufacturing, sheet metal processing is accelerating its transformation towards intelligence. Smart factories achieve interconnection and real - time data monitoring of equipment by introducing industrial robots, the Internet of Things (IoT), and artificial intelligence (AI) technology. For example, the intelligent laser cutting system launched by TRUMPF in Germany can automatically identify the sheet size and material and adjust the cutting path according to preset parameters, reducing manual intervention and increasing production efficiency by more than 20%. In addition, AI algorithms can also optimize the nesting scheme, further increasing the material utilization rate by 5% - 8%, effectively reducing the enterprise's operating costs.

(2) Green Manufacturing and Sustainable Development

Driven by the "dual - carbon" goal, the sheet metal industry is actively exploring green processes. On the one hand, technologies such as dry cutting and coolant - free processing are promoted to reduce the pollution of cutting fluid. On the other hand, recyclable materials and environmentally friendly surface treatment processes are developed. For example, water - based coatings and powder spraying technologies are gradually replacing traditional solvent - based coatings, significantly reducing the emission of volatile organic compounds (VOCs). At the same time, through the waste recycling system, the leftover materials are reused. For example, the cut - off remnants are remelted to make new sheets, realizing the recycling of resources.

(3) Challenges and Countermeasures Faced by the Industry

Although the prospects are broad, the sheet metal industry still faces multiple challenges. The cost of equipment renewal is high, and small and medium - sized enterprises can hardly afford high - end equipment such as laser cutting machines and CNC bending centers. There is a shortage of technical talents, and there is an insufficient supply of compound technicians who are proficient in programming and equipment debugging. The market competition is fierce, and product homogenization is serious. Enterprises need to continuously improve their customized service capabilities. In response, enterprises can cultivate professional talents through school - enterprise cooperation, introduce the leasing model to reduce equipment investment, and at the same time, use 3D modeling and virtual simulation technology to optimize the design process to quickly respond to customer needs and enhance market competitiveness.

Sheet metal fabrication occupies a pivotal position in modern manufacturing with its unique charm and excellent performance. With the continuous progress of technology, sheet metal fabrication is also constantly innovating and developing. New equipment, processes, and materials are emerging, injecting strong impetus into the development of various industries and bringing more high - quality and practical products to our lives. In the future, sheet metal fabrication will continue to move forward on the path of intelligence and greenness, writing a new chapter in the field of metal processing.