CNC Technology: The Core Machining Technology in Modern Manufacturing

In today's highly automated modern manufacturing industry, CNC (Computer Numerical Control) technology serves as the "central nervous system" of manufacturing. With its high precision, high efficiency, and high degree of automation, it has become a key driving force for the intelligent development of the manufacturing industry. From precision aerospace components to daily 3C electronic products, CNC technology is ubiquitous, profoundly influencing product quality and production efficiency.

Basic Principles of CNC Technology

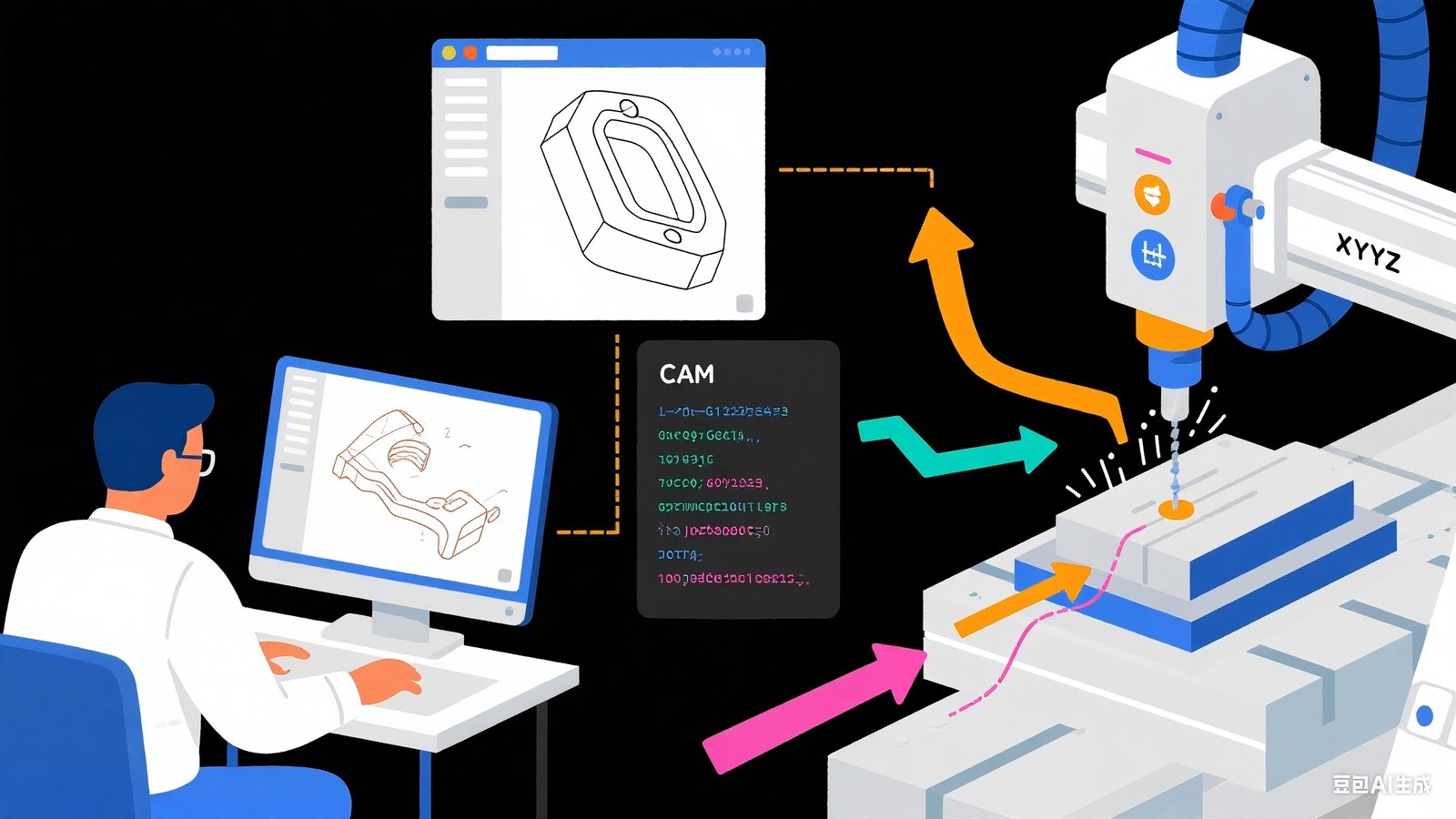

The core of CNC technology lies in transforming digital information into actual machining operations. Traditional machining relies on manual control of machine tools, where operators manipulate the movement of cutting tools and workpieces. In contrast, CNC technology uses a computer control system to precisely control each motion axis of the machine tool (such as the X, Y, Z axes, and even more linked axes) according to pre-written machining programs (usually using G-code and M-code). These programs contain key parameters such as tool paths, cutting speeds, feed rates, and spindle speeds. The machine tool automatically performs machining operations such as cutting, drilling, milling, and grinding on the workpiece based on the program instructions.

In simple terms, CNC technology is like equipping a machine tool with an indefatigable and extremely precise "intelligent operator." For example, when machining a mechanical part with a complex shape, an engineer first uses Computer-Aided Design (CAD) software to create a 3D model of the part. Then, through Computer-Aided Manufacturing (CAM) software, the model is converted into a machining program that the machine tool can recognize. Finally, the program is transmitted to the CNC machine tool, which precisely processes the raw material according to the program instructions, gradually removing excess material until the desired part is formed.

Main Types and Characteristics of CNC Technology

CNC Turning

CNC turning uses the rotation of the workpiece and the feeding of the cutting tool as the basic motion modes. It is mainly used for machining rotary parts such as shafts and discs. During the turning process, the cutting tool moves radially or axially along the workpiece to complete the machining of features such as outer circles, inner holes, threads, and tapered surfaces. Its advantage lies in high precision, with dimensional tolerances controllable within ±0.01mm and a surface roughness Ra value of 0.8 - 1.6μm, which can meet the machining requirements of high-precision parts. For example, key parts such as the crankshaft and drive shaft of an automobile engine can ensure their dimensional accuracy and surface quality through CNC turning, thereby improving the overall performance and reliability of the engine.

CNC Milling

CNC milling performs cutting on the workpiece through a rotating cutting tool and can achieve various types of machining, including planar, contour, and curved surface machining. According to the number of axes, it can be divided into three-axis milling, five-axis milling, etc.:

Three-axis milling: It can machine relatively complex 3D curved surfaces and is widely used in fields such as mold manufacturing and mechanical part machining. For example, in the machining of the cavity of an injection mold, three-axis linkage can quickly and precisely mill out the required shape.

Five-axis milling: Based on the three-axis system, it adds two rotation axes (such as the A-axis and C-axis), enabling multi-angle machining of parts with complex shapes, reducing the number of clamping operations, and improving machining precision and efficiency. In the aerospace field, components with complex curved surfaces such as engine blades and impellers are often machined using five-axis CNC milling to ensure their aerodynamic performance and structural strength.

CNC Drilling

CNC drilling uses a numerical control system to control the positioning and feeding of the drill bit, precisely machining round holes in the workpiece. It can also cooperate with the tapping function to complete the machining of threaded holes. Compared with traditional drilling, CNC drilling has a high degree of automation and accurate positioning, with an accuracy of up to ±0.02mm. It is particularly suitable for scenarios where high precision of hole positions is required in batch production. For example, in circuit board manufacturing, CNC drilling can quickly and precisely drill a large number of tiny holes to meet the requirements of circuit connection.

CNC Grinding

CNC grinding uses a high-speed rotating grinding wheel to grind the workpiece surface and belongs to a precision machining process. It can be divided into types such as surface grinding, external cylindrical grinding, and internal cylindrical grinding, and is mainly used for the finishing of parts with high hardness after quenching. The precision of CNC grinding is extremely high, with dimensional tolerances controllable within ±0.005mm and a surface roughness Ra value as low as below 0.4μm. It is commonly used in the manufacture of precision molds, bearings, gears, and other components with strict requirements for precision and surface quality.

CNC Electrical Discharge Machining (EDM)

CNC EDM is based on the principle of electrical discharge corrosion. Through pulsed discharge between the electrode and the workpiece, the metal material is gradually eroded. It is suitable for the machining of high-hardness and difficult-to-cut materials. This process is divided into electrical discharge forming machining and wire electrical discharge machining:

Electrical discharge forming machining: It uses a shaped electrode to machine the cavity and is commonly used in the machining of complex cavities of injection molds and die-casting molds, enabling shapes that are difficult to achieve with traditional cutting methods.

Wire electrical discharge machining: It uses a thin metal wire (such as molybdenum wire or copper wire) as the electrode and cuts the workpiece along a predetermined trajectory. It is suitable for machining thin parts, special-shaped parts, and precision components and is widely used in industries such as electronics and mold manufacturing.

Key Advantages of CNC Technology

High Precision and Stability

CNC machine tools are equipped with high-precision servo motors, ball screws, and guide rail systems. Combined with the precise control of the numerical control system, they can ensure the consistency of machining precision. Even during long-term continuous machining, they can maintain stable precision performance, reducing errors caused by manual operation and meeting the requirements of industries with extremely high precision requirements, such as aerospace and medical equipment.

Efficient Automated Production

CNC machine tools can operate automatically according to pre-programmed programs without the need for real-time manual intervention, greatly improving production efficiency. At the same time, through multi-axis linkage and compound machining functions, multiple machining processes can be completed in a single clamping, reducing clamping errors and auxiliary time. It is suitable for batch production and the machining of complex parts.

Flexible Machining Adaptability

By simply modifying the machining program, the machining of different parts can be quickly switched without the need to readjust the machine tool structure. Whether it is a simple part or a part with complex curved surfaces and precise structures, CNC technology can achieve machining through programming, meeting diverse product requirements. It is particularly suitable for industries with rapid product updates.

Ability to Machine Complex Shapes

With the help of advanced CAM software and multi-axis linkage technology, CNC technology can machine complex shapes that are difficult to achieve with traditional machining methods, such as the turbine blades of aircraft engines and the personalized interior parts of automobiles. It provides technical support for product design innovation.

Application Fields of CNC Technology

Aerospace Industry

The aerospace field has extremely high requirements for the precision, strength, and reliability of components. CNC technology is widely used in the machining of key components such as engine blades, casings, and landing gears. For example, the aerospace engine blades machined by five-axis CNC milling can optimize aerodynamic performance and improve engine efficiency and thrust by precisely controlling the curved surface shape and dimensional accuracy of the blades. CNC EDM is used for machining components made of difficult-to-cut materials such as high-temperature alloys to ensure their stable performance under extreme working conditions.

Automobile Manufacturing Industry

Automobile manufacturing involves the production of a large number of components, and CNC technology plays an important role in it. From the milling of engine blocks and cylinder heads to the turning and grinding of transmission gears and shaft parts, and then to the manufacturing of body molds, CNC technology ensures the high precision and consistency of automobile components, improving the overall quality and performance of the vehicle. In addition, with the increasing demand for personalized automobiles, the flexible machining characteristics of CNC technology enable it to quickly respond to the production requirements of customized components.

3C Electronic Product Manufacturing

3C electronic products (computers, communications, and consumer electronics) have strict requirements for the precision, miniaturization, and appearance quality of components. CNC technology is commonly used in the machining of components such as mobile phone casings, tablet computer frames, and laptop computer heat dissipation modules. Through high-speed CNC milling and precision machining, ultra-thin and ultra-fine designs of electronic product casings can be achieved, while ensuring surface finish and dimensional accuracy to meet consumers' pursuit of product appearance and texture.

Mold Manufacturing Industry

Molds are the basic process equipment in industrial production, and their precision and quality directly affect the molding effect of products. CNC technology is indispensable in mold manufacturing. Through methods such as milling and EDM, components such as the cavities, cores, and sliders of molds can be precisely machined, ensuring the dimensional accuracy and surface quality of the molds, improving the service life and production efficiency of the molds, and being widely used in the manufacturing fields of injection molds, die-casting molds, stamping molds, etc.

Medical Device Industry

Medical devices have extremely high requirements for safety and reliability. CNC technology is used in the manufacture of medical devices implanted in the human body (such as artificial joints and orthopedic implants) and key components of medical equipment (such as the frames of CT machines and surgical instruments). Through high-precision machining, the dimensions of medical devices can be ensured to match human tissues highly, reducing the rejection reaction. At the same time, strict quality control and stable machining precision ensure the safety and effectiveness of medical devices.

Challenges and Development Trends of CNC Technology

Although CNC technology has become the core technology in modern manufacturing, it still faces some challenges. On the one hand, high-end CNC machine tools and numerical control systems rely on imports, and the degree of autonomy in core technologies needs to be improved. On the other hand, with the increasing complexity of products and the improvement of precision requirements, higher requirements are put forward for the programming technology, machining efficiency, and intelligent level of CNC technology.

In the future, CNC technology will develop in the following directions:

Intelligent and automated upgrading: Combining artificial intelligence and Internet of Things technologies to achieve intelligent monitoring, fault prediction, and adaptive machining of CNC machine tools, improving production efficiency and machining quality. For example, by using sensors to collect machining data in real-time and using AI algorithms to optimize machining parameters, the scrap rate can be reduced.

Multi-axis linkage and compound machining: Developing linkage machining technologies with more axes (such as seven-axis and nine-axis) and compound machining processes such as turning-milling compound and milling-grinding compound to further improve the machining ability and production efficiency of complex parts.

Green manufacturing: Researching environmentally friendly cutting fluids and optimizing machining processes to reduce energy consumption and environmental pollution, promoting the development of CNC technology towards green manufacturing.

High precision and micro-nano machining: Breaking through the existing precision limits and expanding into the field of micro-nano machining to meet the requirements of industries such as semiconductors and optics for ultra-precision machining.

As the core technology in modern manufacturing, CNC technology plays an irreplaceable role in promoting industrial upgrading and product innovation. With the continuous progress of technology, CNC technology will continue to inject new impetus into the high-quality development of the manufacturing industry, shaping a more precise, efficient, and intelligent manufacturing future.