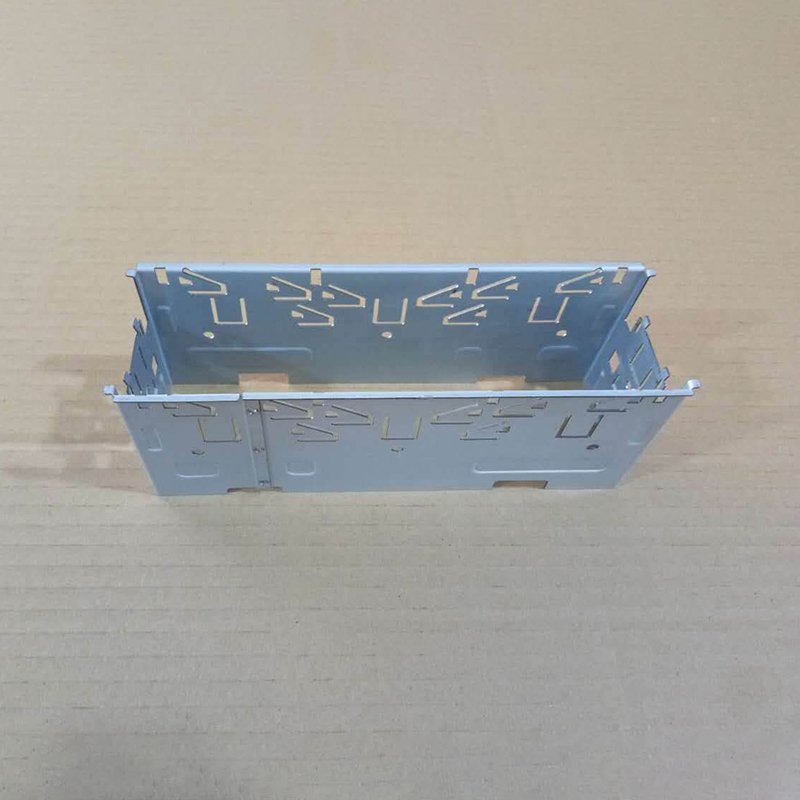

Sheet Metal Fabrication: A Practical Tool in Industrial Manufacturing

Sheet metal fabrication, as a traditional yet dynamic metal processing technology, has a long history in the field of industrial manufacturing. With the continuous development of industrial products towards diversification, lightweight, and high performance, sheet metal fabrication technology has also been evolving. From early manual operations to the widespread use of advanced technologies such as laser cutting, CNC bending, and robotic welding today, sheet metal fabrication plays an indispensable role in many industries such as automotive, electrical appliances, and communications, becoming a practical means in industrial manufacturing.

Technical Advantages

Strong Process Flexibility

In the manufacturing process of electrical control cabinets, the process flexibility of sheet metal fabrication is fully demonstrated. Laser cutting technology can achieve high-precision cutting with a narrow slit of 0.1mm, and CNC bending technology can control the bending angle accuracy within ±0.5°. Through the flexible combination of different processes, it can meet more than 95% of non-standard design requirements. An electrical control cabinet manufacturing enterprise has shortened the production cycle of control cabinets from the original 15 days to 7 - 8 days by optimizing the combination of sheet metal fabrication processes, and the proportion of customized orders has increased from 30% to 60% - 70%.

Significant Cost-Effectiveness

In the scenario of small to medium batch production (500 - 5000 pieces), sheet metal fabrication has obvious cost advantages compared with the injection molding process. Taking the production of chassis shells as an example, the unit cost of sheet metal fabrication is about $15 - $25, while the mold opening cost of the injection molding process alone is $50,000 - $100,000. In small batch production, the unit cost of the injection molding process is as high as $50 - $80. In addition, sheet metal fabrication does not need to bear the costs of mold maintenance and replacement, further reducing the overall production cost.

Lightweight Advantage

In the automotive industry, in order to meet the increasingly strict fuel economy and environmental protection regulations, lightweight has become an important development trend. Using high-strength steel sheet metal parts can reduce the body weight by 10% - 15% while ensuring the body strength. For example, after using sheet metal parts in some structures of the Tesla Model Y, the single-piece weight is 8% - 10% lighter than traditional stamped parts, the corresponding vehicle's driving range is increased by 3 - 5 kilometers, and the vehicle's handling performance is also improved to a certain extent.

Technical Disadvantages

Relatively Insufficient Machining Accuracy

In the processing of precision brackets for electronic devices, there is an obvious gap between the accuracy of sheet metal fabrication and CNC machining. The springback error of sheet metal bending is usually about ±0.3mm, which requires secondary correction. The accuracy of brackets processed by CNC machining can reach ±0.05mm without secondary correction. This makes the defective rate of sheet metal brackets 10% - 15% higher than that of CNC machining, which limits the application of sheet metal fabrication in the manufacture of electronic devices with high precision requirements.

Labor Intensity and Skill Dependence

Manual welding is one of the most labor-intensive links in sheet metal fabrication. The daily welding length of workers in the welding position can reach 20 - 30 meters. Long-term engagement in this work is likely to lead to occupational strains, and the occupational strain rate is about 35%. At the same time, the training cycle of skilled welders is relatively long, generally taking 2 - 3 years, and the talent loss rate is relatively high, exceeding 20%. This makes the enterprise's annual cost of welder training increase by $150,000 - $200,000, increasing the enterprise's operating costs and management difficulties.

Limitations in Appearance and Complex Shapes

In the field of consumer electronics shell manufacturing, sheet metal fabrication has limitations in appearance and complex shapes. For shells with complex curved surfaces, sheet metal fabrication requires multiple processes for splicing, and the width of the surface splicing seam is about 0.2 - 0.3mm. The injection molding process can achieve one-piece molding, seamless and with better appearance texture. This results in a relatively low market share of sheet metal shells in the high-end consumer electronics market, less than 15%.

Customer Selection Suggestions

Enterprises with Small to Medium Batch Production Requirements

For a communication base station cabinet manufacturer with an annual output of 2,000 - 3,000 units, using the sheet metal fabrication process, the unit cost is $30 - $40 lower than the injection molding process, and the enterprise can save $600,000 - $800,000 in costs per year. Moreover, sheet metal fabrication can quickly respond to the customization requirements of operators, and the order delivery cycle can be shortened by 40% - 50%, which helps the enterprise gain an advantage in market competition.

Industries Sensitive to Weight

When a drone enterprise manufactures the fuselage, using an aluminum alloy sheet metal fuselage can reduce the weight by 20% - 25% compared with a traditional plastic fuselage. This increases the drone's flight time by 10 - 15 minutes, and under the same load condition, the effective load capacity is increased by 15% - 20%. For the drone industry, which is extremely sensitive to weight, the lightweight advantage of sheet metal fabrication can significantly improve product performance.

Industries with High Requirements for Product Practicality

When an industrial equipment manufacturer produces equipment shells, using sheet metal shells has a high impact strength of up to 50J/m², 3 - 4 times higher than plastic shells. In a harsh industrial environment, sheet metal shells can effectively protect internal equipment, reducing the equipment failure rate by 40% - 50% and maintenance costs by 30% - 40%. For the industrial equipment industry that focuses on product practicality and durability, sheet metal fabrication is an ideal choice.