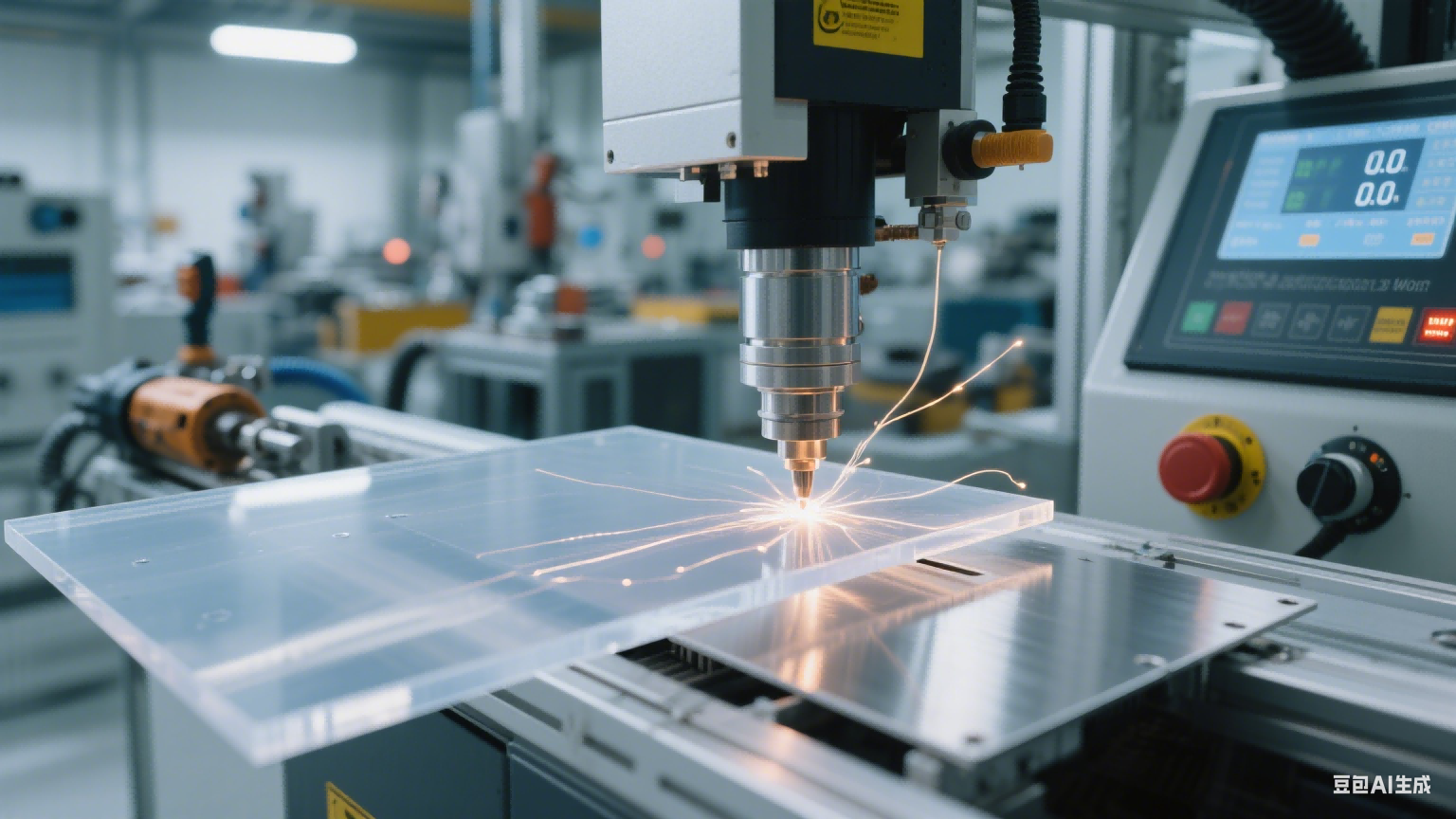

Ultrasonic Welding: An Efficient Process for Joining Plastics and Metals

With the widespread application of plastic products and lightweight materials in various industries, efficient and reliable joining processes have become crucial. Ultrasonic welding utilizes high-frequency vibration energy to generate heat through friction on the welding surfaces, achieving the fusion and connection of materials. In industries such as electronics, automotive, and packaging, it provides a fast and environmentally friendly solution for joining plastics to plastics and metals to plastics.

Technical Advantages

Fast Welding Speed and High Efficiency: Ultrasonic welding has an extremely short welding time. Generally, the welding time for a single welding point is only 0.5 - 2 seconds, making it suitable for large-scale production. In the assembly of mobile phone cases, the use of ultrasonic welding technology can complete the welding of dozens of cases per minute, significantly improving production efficiency.

Good Welding Quality: The welds formed by ultrasonic welding have high strength and good sealing performance. For plastic welding, the weld strength can reach 80% - 90% of the base material strength. In the welding of automotive fuel tanks, the ultrasonic-welded fuel tanks have good sealing performance, effectively preventing fuel leakage and ensuring driving safety.

Environmentally Friendly and Pollution-Free: Ultrasonic welding does not require the use of auxiliary materials such as glue and solvents, avoiding chemical pollution. At the same time, no waste gas, wastewater, or waste residue is generated during the welding process, meeting the green and environmental protection development requirements of modern manufacturing.

Technical Disadvantages

High Requirements for Material Compatibility: Ultrasonic welding has strict requirements for the acoustic properties and melting points of materials. Only materials with similar acoustic properties and similar melting points can be well welded. For example, when welding different types of engineering plastics, a large number of tests are required to determine the appropriate welding parameters; otherwise, poor welding may occur.

Limited Weld Joint Forms: Ultrasonic welding is suitable for simple joint forms such as lap joints and butt joints. For complex three-dimensional joints or multi-layer material connections, the welding difficulty is relatively large. In the connection of some special-structured components, other welding processes may need to be combined.

High Equipment Cost: The price of high-performance ultrasonic welding equipment ranges from tens of thousands to hundreds of thousands of yuan. For small enterprises or small-batch production projects, the equipment investment cost is relatively high. In addition, the key components of the equipment, such as transducers and welding heads, have a certain service life, and the replacement cost should not be ignored.

Customer Selection Suggestions

Electronics and Electrical Appliance Manufacturing Enterprises: In the assembly of electronic devices such as mobile phones, tablets, and smart watches, ultrasonic welding can be used for shell welding and battery packaging, ensuring the sealing and aesthetics of the products. Electronics companies such as Apple and Huawei widely use ultrasonic welding technology to improve product quality and production efficiency.

Automotive Parts Suppliers: For the welding of automotive interior parts (such as dashboards and door panels), fuel tanks, filters, and other components, ultrasonic welding can meet the requirements for strength and sealing. Automotive parts suppliers such as Bosch and Continental use ultrasonic welding technology to enhance product competitiveness.

Packaging Industry: For the sealing welding of plastic packaging boxes and plastic bottles, ultrasonic welding has a fast speed and good effect, which can improve packaging production efficiency and reduce packaging costs. In the packaging fields of food, cosmetics, etc., ultrasonic welding has been widely used.